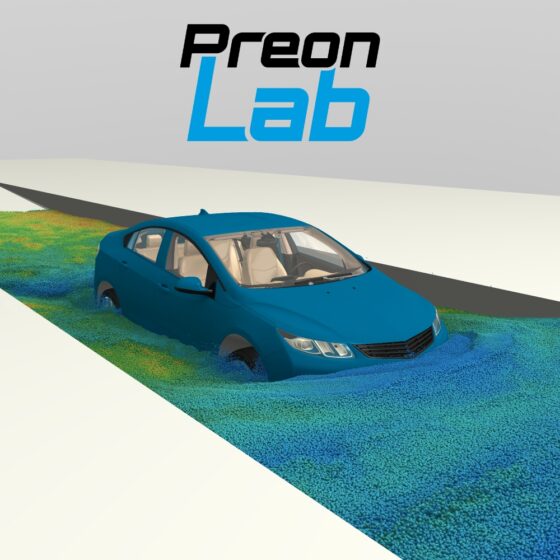

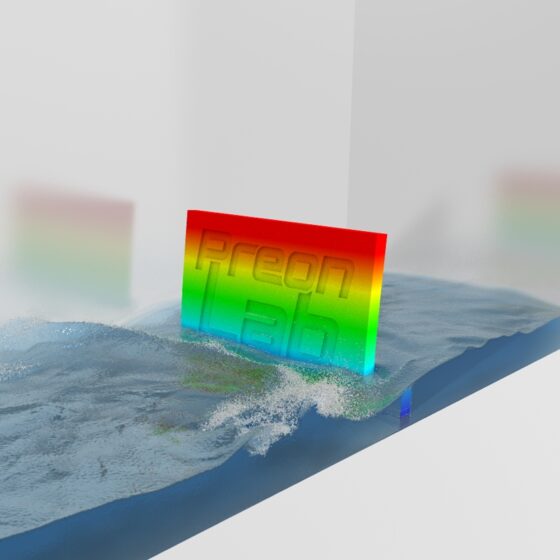

FIFTY2

Innovation corner

There is always one more shot to solve the unsolved problem. Tinkering around, entering the unknown and starting over again is our approach to push the boundaries and create next level innovations. Stay tuned for PreonLab updates, new researches, groundbreaking innovation and upcoming events.