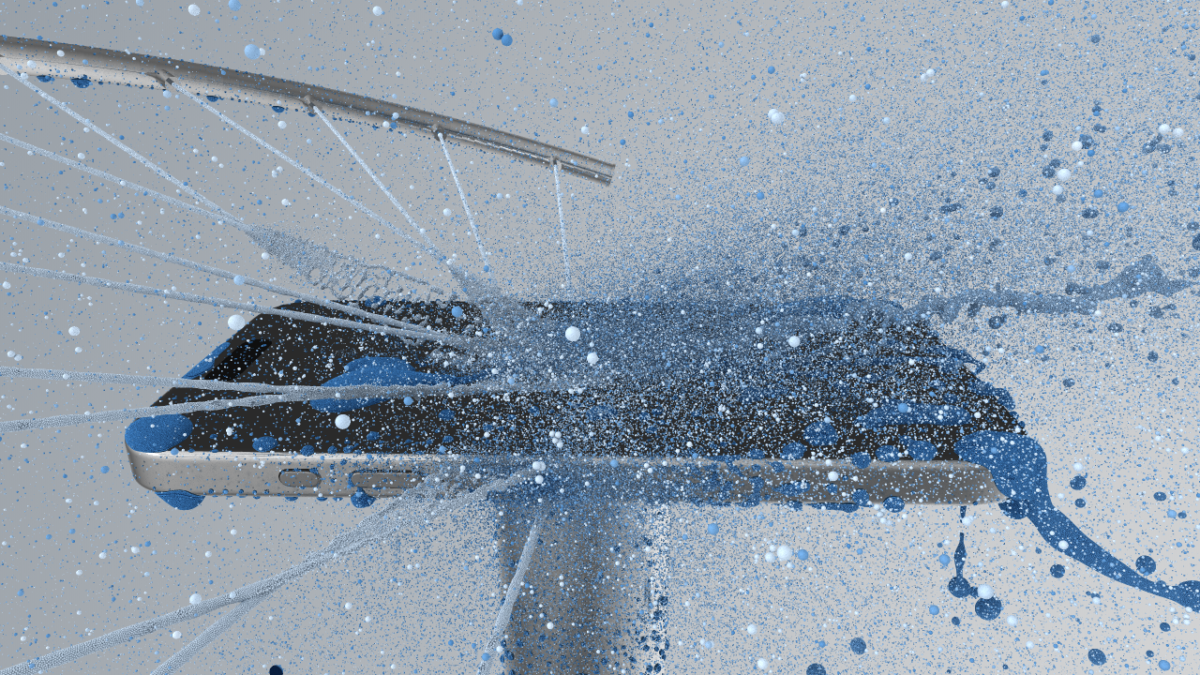

How Mobile Phones Stay Watertight: IP Ratings, Materials, and Virtual Testing

Watertightness in mobile phones is all about keeping water out to protect sensitive internal components. Manufacturers design devices to meet specific standards that measure resistance to water ingress. The Ingress Protection (IP) rating system, set by the International Electrotechnical Commission (IEC), is the gold standard in this regard. An IP rating consists of two digits: the first covers solid particles (like dust), and the second focuses on liquids (like water). For instance, an IP68 rating means that the phone is dust-tight and can withstand submersion in water deeper than 1 meter for up to 30 minutes. These ratings are verified under controlled conditions in specialized laboratories for precision and reliability.

Learn more about IP ratings: Ingress Protection Ratings Guide.