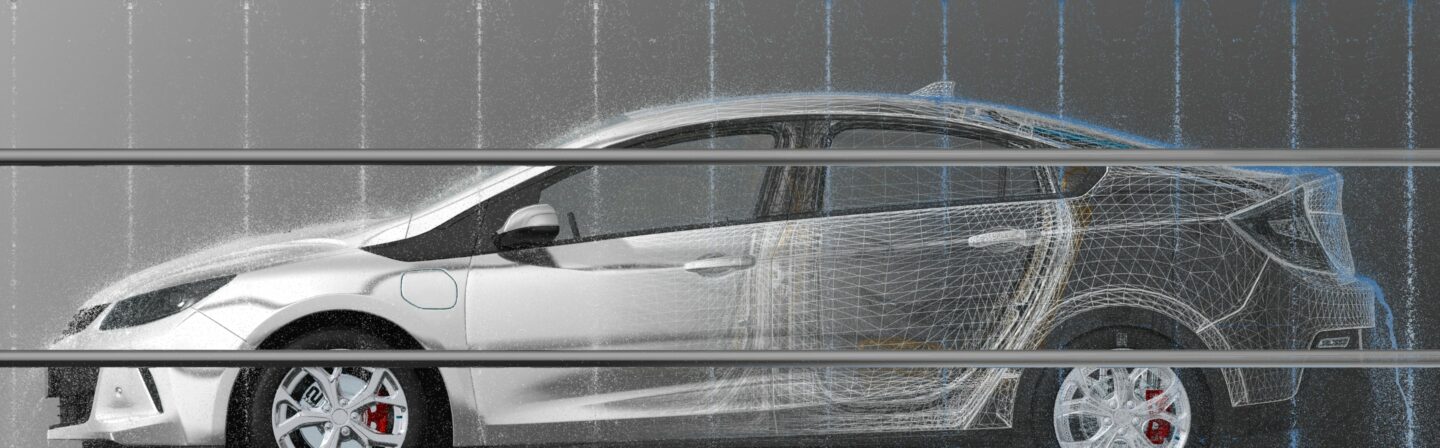

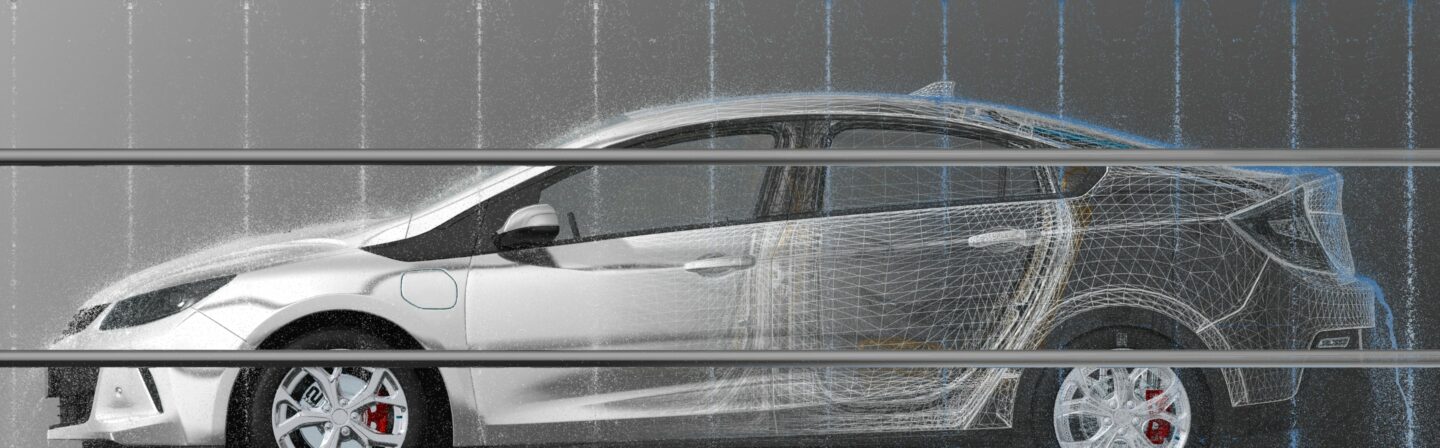

The safety of a car is influenced by environmental factors such as rain, snow, and mud. To prevent such influences from becoming a hazard, OEMs are required to design the vehicle body appropriately. A good design ensures clear vision of the road ahead, side mirrors and windows for the driver, as well as cameras and sensors for autonomous vehicles, reducing the need for various cleaning devices like sprayers or heaters. Avoid having to make design changes in the late stages of your development process by achieving early confidence in your designs that not only meet aesthetic requirements, but also increase the safety and comfort of your product. Save costs and time by testing in a virtual and controlled environment. While at the same time, increasing the safety and comfort of your product.

PreonLab fulfills your simulation needs and lets you efficiently simulate various different soiling scenarios. No matter if you are just interested in a specific part of the vehicle design or if you need to get insights about the whole system in interaction with different weather conditions: PreonLab keeps you covered without the necessity of a physical prototype or a costly climate tunnel.

You can easily perform a full wetting analysis and evaluate the flow paths while staying warm and dry.

Vehicle soiling simulations can provide valuable insights into how transient and steady airflow, surface geometry, and dynamic driving conditions influence the accumulation of water, snow, mud, and other contaminants on a vehicle’s surface. Engineers can use wetting sensors to identify critical soiling zones such as regions around cameras, sensors, windshields, and mirrors, and evaluate the effectiveness of design modifications. They can perform simulations to optimize aerodynamic performance towards reducing the impact of soiling, and leverage virtual insights to support the development of cleaner, safer, and more sensor-reliable vehicle designs without relying solely on physical prototypes.

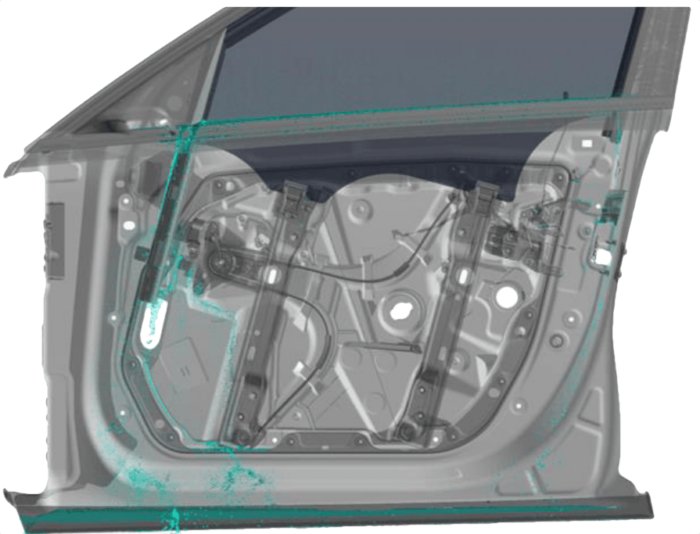

Presented as “CFD Simulation of a Vehicle Driving in Snow” by D. Bäder, S. Eibl, C. Wolf, A. Oliva and P. Kolar from Audi AG and AVL Deutschland GmbH at the AVL Virtual Simulation Conference 2021. The setup has been realized with a static car, while the ground is moving and turning wheels have been modelled in PreonLab accordingly. In PreonLab, an Area Source has been specified, generating a specific layer of snow in front of the car. In order to reduce numerical effort, the snow particle behind the tires are deleted, saving a considerable amount of time. Of course, attention should be paid to details of the tire’s geometry since this is crucial in order to resemble the actual behavior of the snow interacting with the tire. Since it is often difficult to get an accurate tire geometry, the wheel was scanned separately with a high amount of resolution, so it was possible to take the winter tire’s profile into account in PreonLab simulation, to get more realistic snow accumulation in the wheelhouse.

Video 1: Simulation Performed by AUDI Showing the Accumulation of Snow in the Wheelhouse.

The world is changing, and so is Audi. In order to keep up with the challenges faced in the context of digitalization, Audi established the simulation of water in the development process.

Video 2: Simulation Performed by AUDI Showing Wipers Wiping Away Rainwater Falling on the Vehicle’s Windshield.

The Chair of Automobile Engineering at the TU Dresden is investigating and developing a tool chain for virtual water management for the automotive industry. Multiple simulation tools were evaluated for the task of predicting water paths on a car door. PreonLab compared favorably against other evaluated tools in terms of validated results, performance and usability:

The study was conducted by Daniel Wickert as part of his diploma thesis and was supported by Daimler AG.

Fully dynamic sprinkling simulation considering imported air flow velocities caused by the airstream of the moving vehicle. Additionally, the wiper activity is considered making this an example of a real world approximation of a vehicle driving in extensive rain.

Video 3: Dynamic Sprinkling Simulation Showing the Windshield of a Vehicle Driving Through Extensive Rain.

Since aerodynamic effects on the vehicle play a significant part in influencing the soiling pattern, they need to be considered during the simulation. In fact, considering the effects of transient airflows is essential, especially for simulations aimed at capturing soiling patterns on the side windows due to A-pillar and side-mirror overflows, or the rear end of the vehicle due to splashing.

PreonLab supports the import of transient as well as steady-state air flows via the CSV format or the EnSight Gold format. The imported airflow can then be visualized with the help of a Vector Field Visualizer and its influence can be considered during simulation via one-way coupling.

Video 4: Impact of Coupling a Pre-Computed Airflow from the Air-Conditioning on Simulation Results.

The flat jet source will help you to recreate some of your real scenarios even more accurately in PreonLab and is especially useful for washing cases.

There is now a possibility to distinguish whether a drop of water touched the sensor surface briefly and whether the surface was covered in fluid for minutes. The wetting sensor allows you to colorize the surface given the amount of time it was in contact with fluid.

Video 5: Car Wash Simulation Visualizing Wetting on the Vehicle’s Surface.

In PreonLab, snow is computed as an elasto-plastic continuous material, where the elastic part is solved implicitly. Different types of snow can be modelled ranging from chunky to powdery snow, from wet and adhesive to dry. Just like the Preon fluid solver, the snow solver can handle any imported geometries without meshing and offers competitive performance.

This opens a variety of interesting applications. For example, snow fall on a vehicle to optimize sensor locations for autonomous cars or the efficiency analysis of a snowplow.

Video 6: Compilation of Simulations Showing Snow Accumulation in Wheelhouse, Tailgate Opening in Snow, and Snow Accumulated due to Snowfall.

Using PreonLab, engineers can simulate the complex, dynamic behavior of mud- and marsh-like fluids using the Herschel-Bulkley model for non-Newtonian fluids, observing how rotating wheels splash the fluid. Flexible mudflaps can be modeled as linear elastic materials to capture the Fluid-Structure Interaction (FSI) between the splashing fluid and the mudguards. These FSI simulations allow engineers to consider the flap’s deformation and response to impact forces, helping to evaluate design efficiency and coverage effectiveness—all before any physical prototype is built.

The following video shows a soiling pattern that occurs when marsh-like fluid is flung up onto the vehicle’s side by the wheels, and how the use of a flexible mudflap helps mitigate this effect.

Video 7: Soiling Simulation with a Flexible Mudflap – Fluid-Structure Interaction (FSI).

PreonLab offers a powerful and versatile platform for simulating a wide range of environmental soiling scenarios, including rain, snow, and mud, without the need for costly physical prototypes or climate tunnels. By leveraging the advanced Smoothed Particle Hydrodynamics (SPH) method, PreonLab enables engineers to efficiently model complex interactions between fluids, vehicle surfaces, and surrounding airflow. The software’s ability to simulate non-Newtonian fluids using the Herschel-Bulkley or Carreau-Yasuda models and capture Fluid-Structure Interactions (FSI) for deformable components broadens the range of scenarios from which valuable insights into vehicle design and sensor placement can be gained. These capabilities allow for early design optimization, reducing development costs and time while enhancing vehicle reliability and safety.