Expanding SPH Terminology: Continuous Particle Size (CPS)

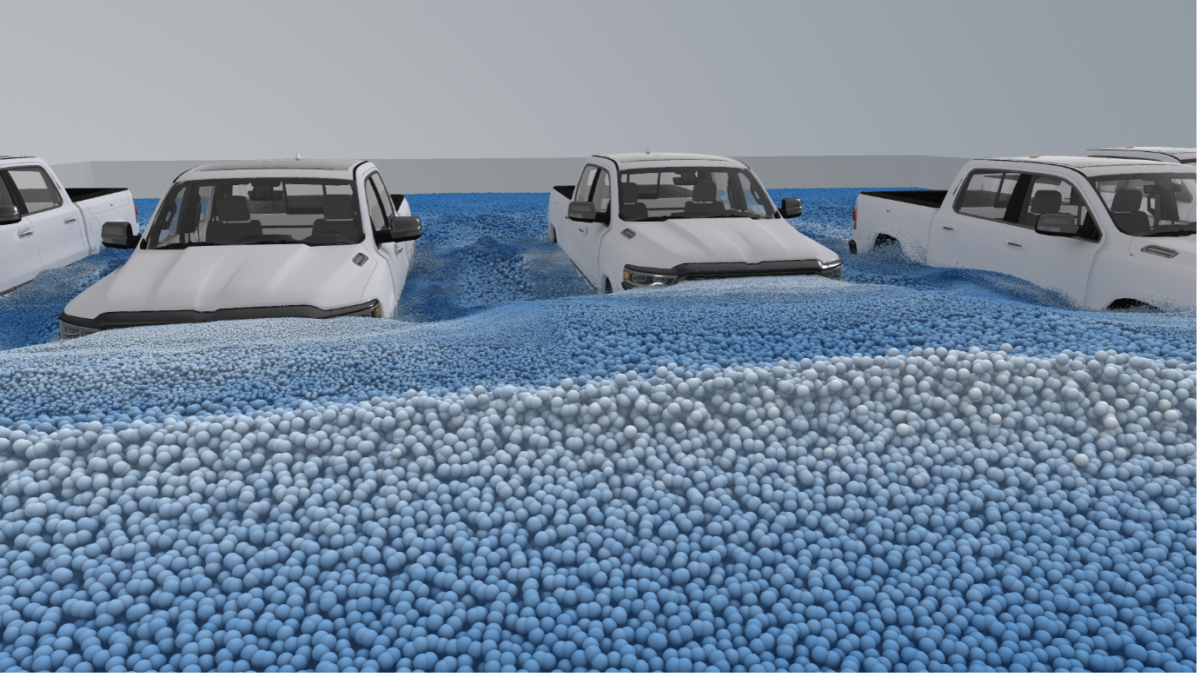

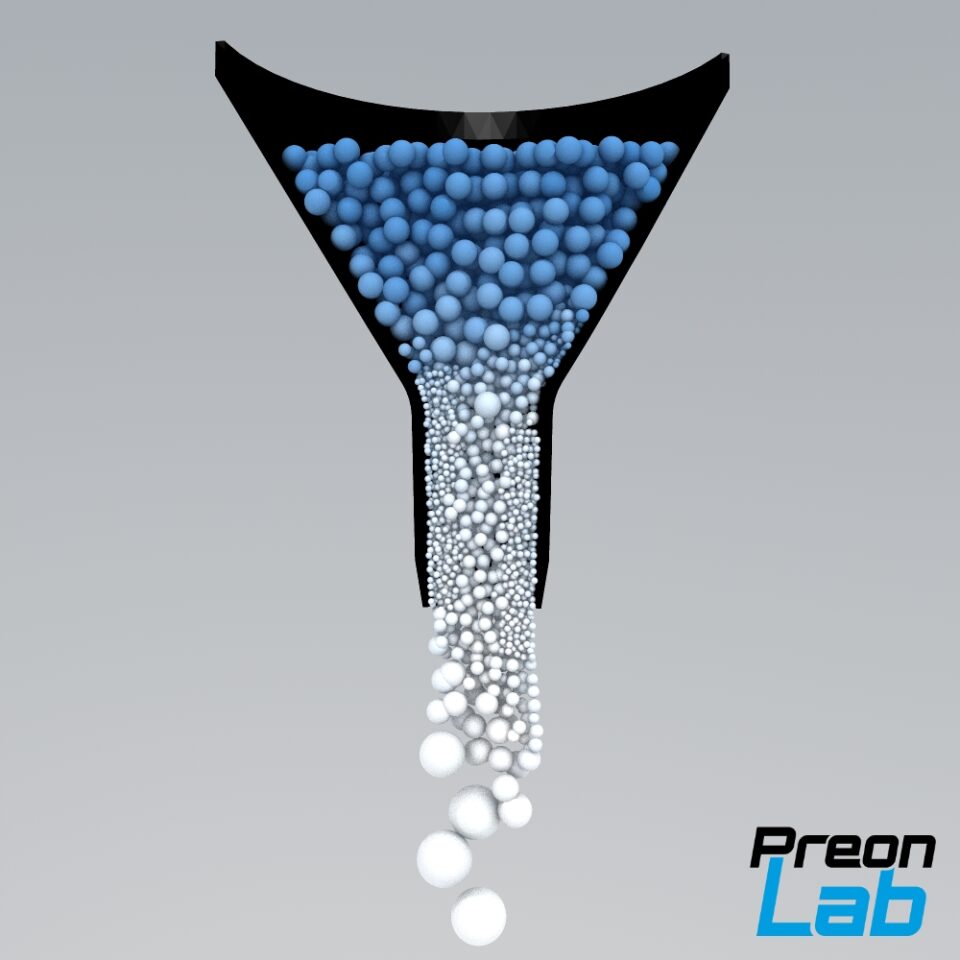

In the field of Computational Fluid Dynamics, the pursuit of simulation efficiency and accuracy is the name of the game. These two seemingly contradictory goals often appear at opposite ends of the spectrum. But is this always the case? Is it possible to have both efficiency and accuracy without making sacrifices? We believe it is. And we’re not referring to hardware efficiency, a topic extensively covered in our previous articles (see here and here). What we mean is state-of-the-art software development which is in the DNA of the FIFTY2 team. What we want to talk about in detail is one of our most prominent features available only in PreonLab. We named it Continuous Particle Size, or in short, CPS.