Whether it’s through a flooded street, a river crossing, or a deep puddle, driving through water can test a vehicle’s ability to withstand submerged conditions, and pushes its design and engineering to the limit. For conventional vehicles, water entering the air intake system poses a significant risk by disrupting the engine’s combustion process through airflow obstruction or, in severe cases, causing critical damage if it reaches the engine cylinders. For electric vehicles, safety concerns arise from the pressure exerted on the underbody, potentially damaging battery packs when driving through deep water. Identifying and addressing these hazards early in the design phase is crucial. Consequently, vehicle water wading tests are conducted during the development of vehicle prototypes to ensure safety and functionality on the road.

Traditionally, physical tests are performed by driving prototypes through various water depths at different speeds before advancing to the next design stage. However, gathering all relevant measurements from physical experiments is not trivial. Moreover, the late detection of failure modes can lead to delays and necessitate design changes in the production prototype, resulting in increased costs and time expenditures. A more efficient approach involves developing virtual prototypes and conducting simulations to identify potential failure modes before building physical prototypes.

Rapid and Efficient:

Rapid virtual prototyping relies on fast setup and computational times to deliver insights quickly. The short turnaround time allows for the simulation and analysis of multiple virtual prototypes, enabling the filtering of suitable designs before creating physical ones.

PreonLab uses an implicit formulation of Smoothed Particle Hydrodynamics (SPH), a mesh-free fluid simulation method, to analyze critical parts of the vehicle during water wading scenarios. Additionally, PreonLab provides the Full Car Suspension Model (FCSM) to account for vehicle suspension in the simulation. You can conduct comprehensive wetting analyses, measure water heights, predict underbody forces, assess flow rates, and understand flow paths in a short amount of time. PreonLab equips you with the right tools to quickly evaluate your designs based on any metric you’re interested in, for a wide range of scenarios.

Video 1: Water Wading Simulation in PreonLab.

Fast and Reliable:

Quick and efficient simulation is important, but it’s equally crucial that the results are realistic and accurate. Johann Idoffsson conducted an evaluation of PreonLab in simulating water wading scenarios for Volvo Cars. The assessment involved comparing PreonLab not only with the previous tool chain, which was based on a grid-based CFD method, but also with real-world test bed results.

Despite the limited time available during a master’s thesis, the user-friendly UI of PreonLab allowed for the development of a sophisticated methodology. Click on the button on the right and find out more how PreonLab has helped engineers at Volvo.

Video 2: Water Wading at Volvo.

By performing vehicle wading simulations using PreonLab, you can quickly gain insights into preventing water ingress into critical components, understanding wetting in vehicle design, and analyzing the hydrodynamic forces acting on the vehicle and its suspension system to assess safety and performance under submerged conditions. PreonLab equips you with the right tools to quickly evaluate your designs based on any metric you’re interested in, for a wide range of scenarios.

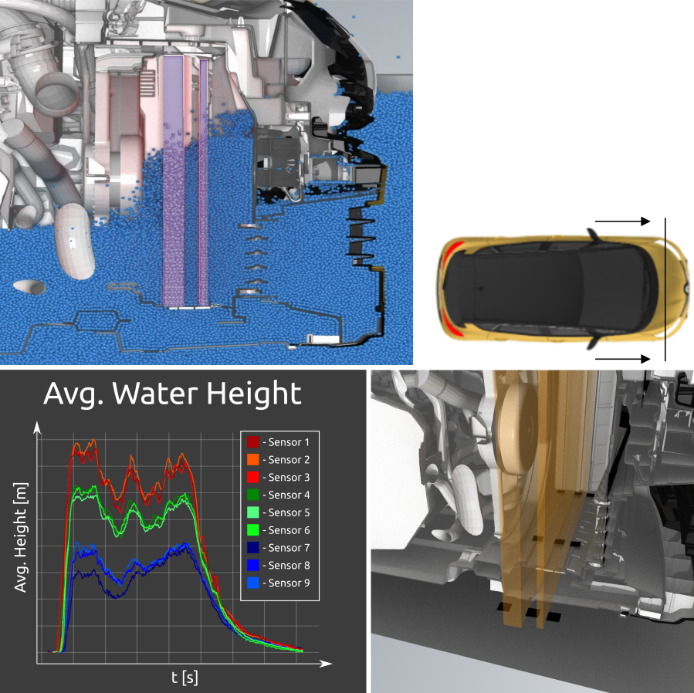

Water ingress due to vehicle water wading refers to the unwanted entry of water into a vehicle’s internal components, such as the engine, transmission, electrical systems, or interior. Using PreonLab, engineers can analyze the flow of water into these critical areas with the help of Height Sensors and Volume Sensors. Height Sensors detect exactly how high water climbs into key regions, while Volume Sensors quantify the amount of water passing through selected regions, such as the air intake under the engine hood.

Figure 1: Analysis of the water ingress in the underhood region.

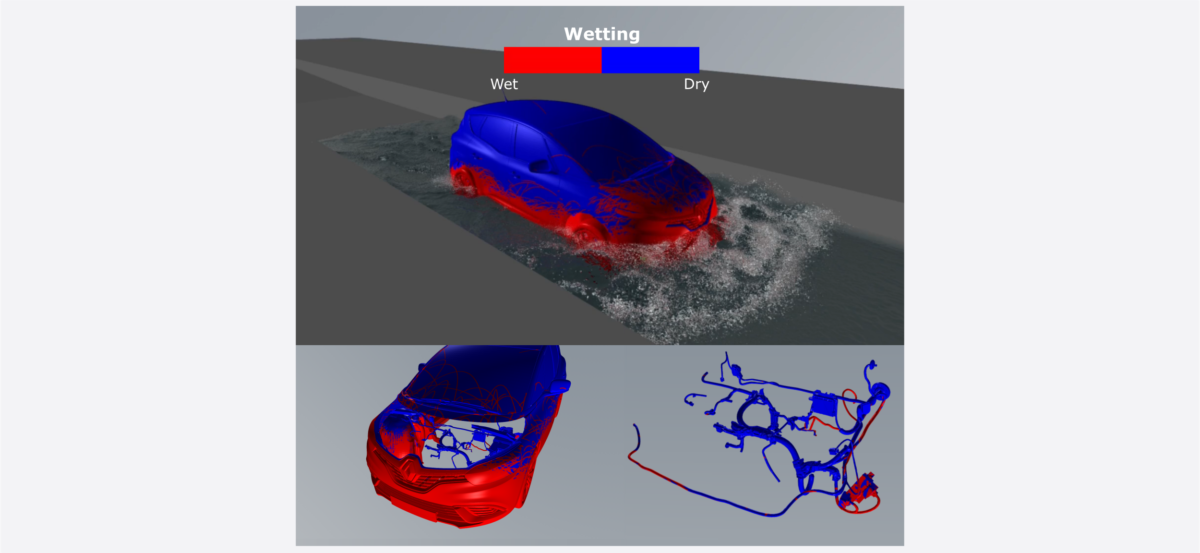

To further evaluate water exposure, Wetting Sensors in PreonLab visualize all internal and external vehicle surfaces that come into contact with water. This allows engineers to identify potential risks and improve design to reduce unwanted wetting. Additionally, the Pathlines Sensor can track fluid particle movement, providing insights into how water flows inside the vehicle and helping optimize protective measures.

Figure 2: Analysis of the wetting on the vehicle’s surface.

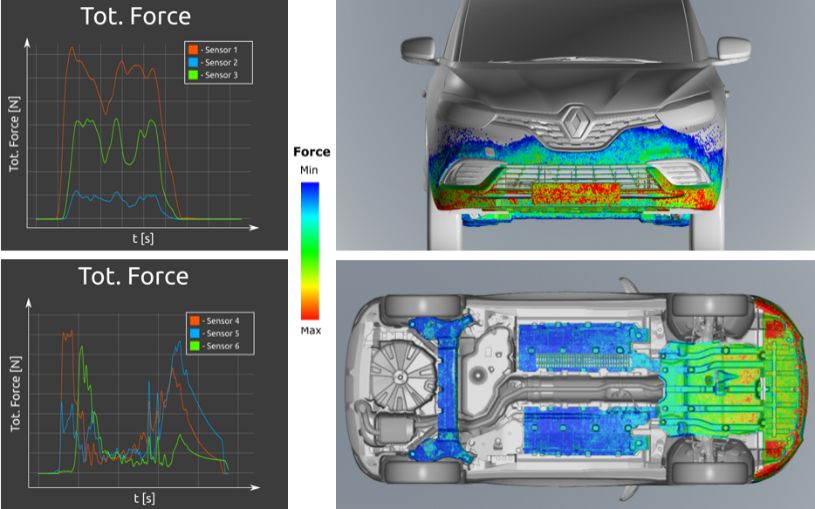

An essential aspect of wading simulations is evaluating the hydrodynamic forces and torques acting on vehicle components such as bumpers and underbody panels. As a vehicle moves through water, these forces generate pressure and drag, potentially affecting stability, handling, and overall safety. Understanding these effects is critical for designing durable and reliable vehicles.

With PreonLab, engineers can use Force Sensors to accurately measure stresses, resulting forces, and torques, including their normal and tangential pressure, and shear components. This detailed analysis enables the evaluation of hydrodynamic loads across various wading scenarios, providing critical insights to help ensure that vehicles maintain performance and structural integrity when driving through water.

Figure 3: Analysis of hydrodynamic forces acting on the vehicle’s surface.

In wading simulations, accurately modeling vehicle kinematics becomes increasingly important as speed increases or water levels rise. Suspension models account for spring deflection based on applied forces, repositioning the sprung mass of the car relative to unsprung parts like wheels. PreonLab’s Full Car Suspension Model (FCSM) calculates deflection forces for each wheel individually, considering fluid forces, acceleration, deceleration, weight shift, and road interactions. As a result, you can analyze how the vehicle interacts with submerged terrain and how hydrodynamic forces affect its suspension system.

This enables detailed analysis of various statistics related to the vehicle’s suspension, like spring and damper forces, as well as the wheel deflections for each individual wheel.

Video 3: Analyzing wheel deflections in a fast water wading scenario using FCSM.

The experimental Virtual Driver feature in PreonLab is a built-in PID controller that mimics the behavior of a real test driver, including acceleration limits. It enables realistic wading simulations even when no experimental velocity profile is available. The controller can be configured individually to mimic different driving styles – for example, a more passive driver, and also allows the specification of a driver reaction time. This makes it possible to gain insights while considering scenarios with different driver behaviors.

In the accompanying showcase, you can see how the virtual driver operates. The target speed is set to 15 km/h, but due to strong hydrodynamic forces, the controller reaches its acceleration limit and is unable to maintain the desired velocity. Once the vehicle leaves the water, the controller is able to accelerate again and reach the target speed.

Video 4: Water Wading Simulation using the Virtual Driver Model

With PreonLab, you can simulate wading through various water depths in a controlled virtual environment without the need for a physical prototype or a wading channel. You don’t need to mount dozens of cameras to get minimal information or depend on a complicated and sensitive sensor setup for measurements. Due to its mesh free approach, quick setup times, efficient solver code, advanced particle refinement and powerful post-processing capabilities, PreonLab can help engineers gain reliable insights into wading simulations conveniently and cost-effectively.