The latest PreonLab 5.2 release saw the introduction of a game-changing new feature in the context of adaptive refinement for particle-based CFD applications – Continuous Particle Size or CPS. As is the case with most great achievements, this was the result of constant efforts and steady progress over the past few years. Let us have a quick look at the various stages of this journey:

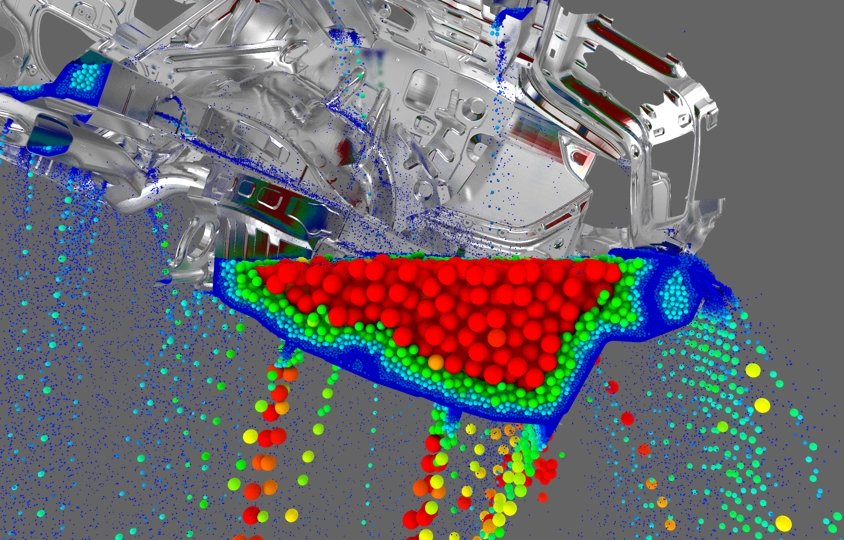

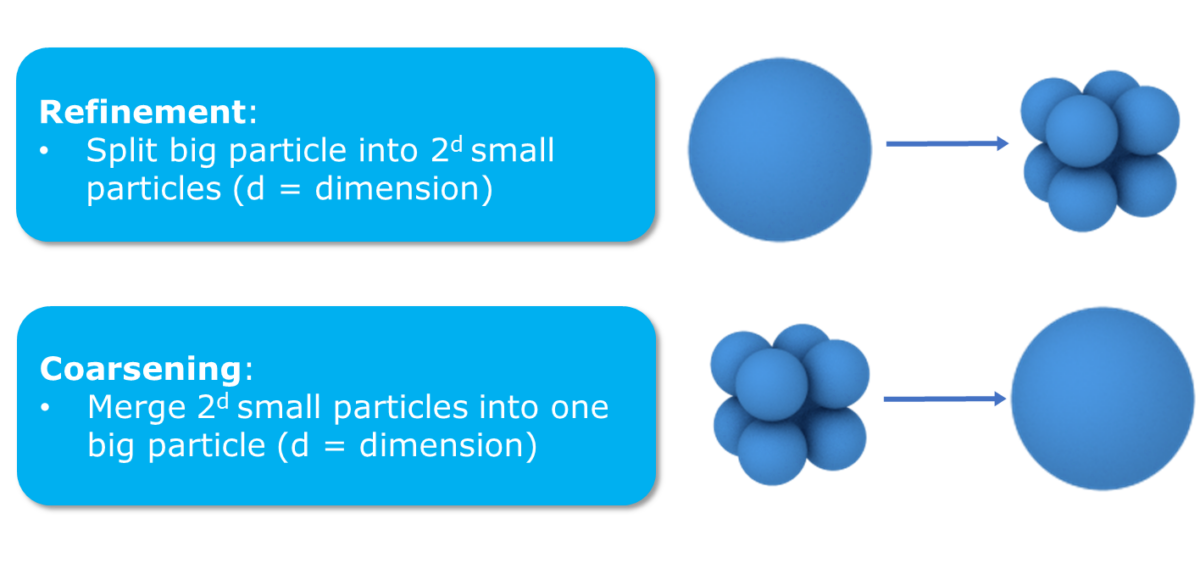

The ability to have adaptive refinement was first introduced to PreonLab users with PreonLab 4.x, where two levels for particle size were introduced. Along with letting the particles in the regions of interest be as fine as required, the simulation for the rest of the bulk fluid volume could be performed with coarser particles. By doubling the size of the finer particles during coarsening, it was possible to reduce the number of particles in the simulation by up to eight times. Refinement was not carried out only within the region of interest, but rather a buffer zone was needed around it for the splitting and merging of particles.

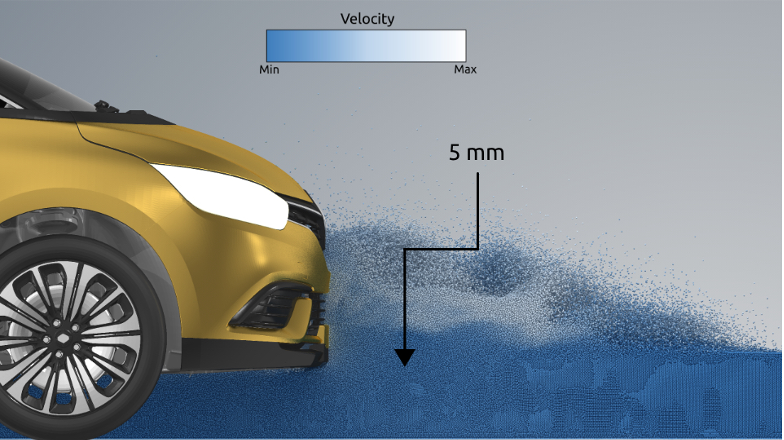

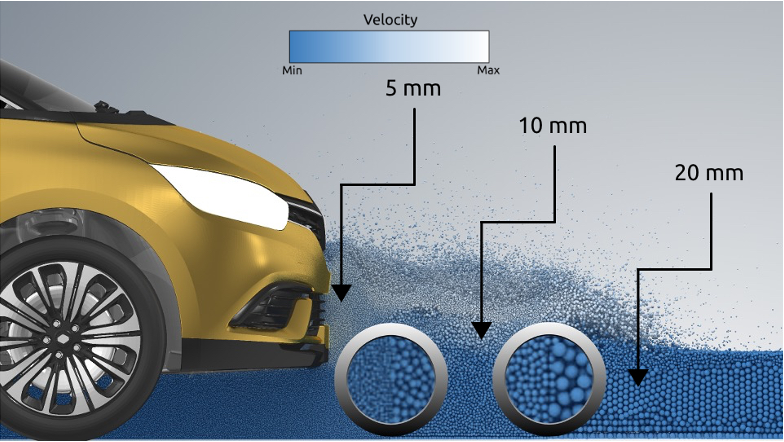

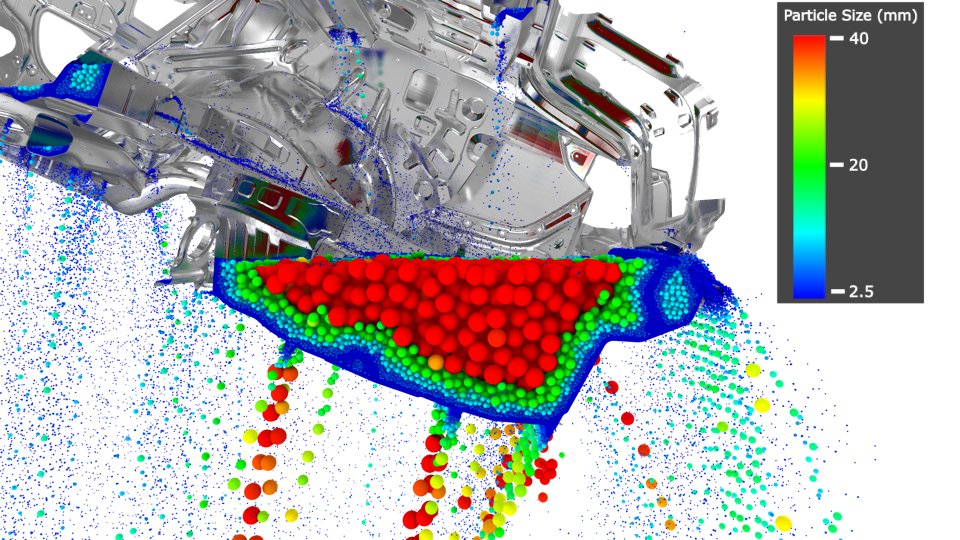

With PreonLab 5.0, it became possible to include 3 levels of refinement within a simulation. This means that three distinct particle sizes could be defined within a single simulation setup. This can be visualized in figure 3 for the water-wading simulation setup. All particles in the region of interest i.e., close to the car geometry, have a particle size of 5 mm, while the particles away from the region of interest become coarser using three levels of refinement. The middle refinement level between the fine and coarse refinements offered some significant benefits. Most importantly, it allowed for an increase in the size ratio between the coarsest and finest particles, thereby reducing the number of particles in the simulation further, by up to sixty-four times. The resulting speed-up is discussed in the article: Getting the Same Result 12x Faster.